Executive Overview

Supply chain optimization is no longer just about efficiency; it is now a sovereignty strategy. As we enter 2026, the convergence of Critical Minerals restrictions, the imminent Digital Product Passport (DPP) mandates, and semiconductor supply bifurcation has created a brief window for action.

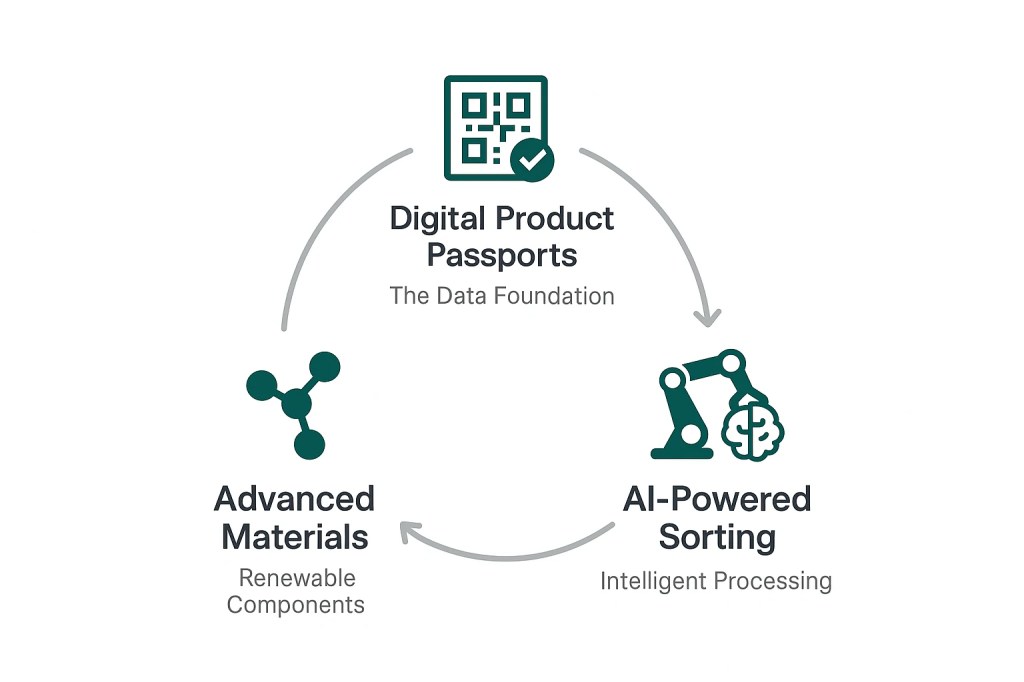

Circular supply chain strategies now deliver three simultaneous returns: regulatory compliance, financial resilience, and geopolitical independence.

For C-suite executives, the data is unambiguous. Companies that fail to map their supply chains beyond Tier-1 suppliers by Q2 2026 face simultaneous penalties: regulatory non-compliance and strategic vulnerability.

This analysis outlines the « Diagnose, Design, Deploy » framework. It provides the blueprint to transition from reactive crisis management to proactive supply chain sovereignty.

Part 1: The Macro Context – Why Now?

1.1 The Great Minerals Decoupling

On January 8, 2026, S&P Global confirmed that the US and EU are in explicit competition to break monopolies over critical minerals processing. This is a geopolitical restructuring of global trade.

State-owned entities currently control the processing of rare earths, lithium, and cobalt. The export controls announced in late 2025 demonstrate the leverage this provides. When similar restrictions hit in April 2025, rare earth prices in the EU spiked 6x.

If your supply chain relies on single-source processing for batteries, semiconductors, or renewable energy components, you have a 36-month window (2026-2029) to pivot. After 2029, dual sourcing will become mandatory and capacity will be scarce.

1.2 The DPP Compliance Cliff (February 2027)

The Digital Product Passport (DPP) is often mistaken for a sustainability initiative. It is not. It is hard data infrastructure.

For battery manufacturers and automotive OEMs, mandatory compliance begins in February 2027.

- The Requirement: You must trace material sourcing (cobalt origin, lithium source) and recycled content percentage.

- The Gap: Current data shows 95% of companies have Tier-1 visibility, but only 42% have Tier-2 visibility.

- The Risk: Implementing the necessary data architecture takes 12-18 months. Companies not in the « Discovery Phase » by March 2026 will miss the compliance window.

1.3 Semiconductor Bifurcation

Supply chains for semiconductors have split into two realities in Q4 2025:

- Analog & Power ICs: Stable. Lead times have normalized.

- AI Compute & Advanced Packaging: Severely constrained.

EV battery systems integrating AI for thermal management are now caught between these two realities. This bifurcation exposes system integrators to volatility. Reliance on a single geographic source for these components is a critical vulnerability.

Part 2: The Framework – Diagnose, Design, Deploy

To navigate this landscape, leaders must adopt a systematic approach.

Phase 1: DIAGNOSE (The Visibility Baseline)

You cannot manage what you cannot see. If you cannot identify the specific mine your cobalt comes from, you are exposed to sovereign risk.

The Reality Gap (2025 Data):

- Tier-1 Visibility: 95%

- Tier-2 Visibility: 42%

- Raw Material Geographic Origin: <30% estimated

Action Plan (Q1 2026): Map your Tier-1 suppliers by raw material category. Identify geographic concentration. If a supplier sources 100% of their input from a single high-risk region, you have binary risk. Use advanced knowledge graphs to identify these hidden dependencies.

Phase 2: DESIGN (The Circular Roadmap)

Circular materials are the ultimate hedge against geopolitical risk. Recycled cobalt has no nationality. It is immune to export restrictions and mining tariffs.

Proof of Concept:

- Circular Republic Consortium (EU): Achieved >80% lithium recovery from spent EV batteries, exceeding 2031 targets.

- Redwood Materials (US): Demonstrating that recovered material costs can be lower than virgin materials, creating a domestic supply source independent of foreign mining.

Action Plan (Q2-Q3 2026): Define circular material sourcing targets. Secure long-term offtake agreements with recyclers now. Capacity is limited. Early movers will lock in supply; followers will face allocation shortages.

Phase 3: DEPLOY (Resilience Infrastructure)

Inaction is expensive. McKinsey data indicates that a single multi-month supply disruption can consume 50-60% of annual profit for a company with 20% EBITDA margins.

Action Plan (Q4 2026 – Q2 2027):

- Build a Supply Chain Control Tower: Integrate ERP and supplier data for real-time visibility.

- Implement Dual Sourcing: For any material with >30% concentration risk, establish a secondary source (70/30 split).

- Establish DPP Infrastructure: Automate data collection from suppliers. Manual spreadsheets will fail against the February 2027 deadline.

Conclusion: The Sovereignty Window

The policies are set. The Digital Product Passport deadlines are fixed. The geopolitical decoupling is active.

Companies face a binary choice:

- React Sequentially: Scramble for DPP compliance in late 2026, then respond reactively to the next supply shock. This creates the highest cost and lowest control.

- Act Systematically: Diagnose visibility gaps now. Design circular loops to reduce import dependency. Deploy resilience infrastructure.

Your supply chain is now your primary sovereignty asset. Build it accordingly.